At Moresuperhard, we strive to provide the highest quality grinding solutions to meet the demanding needs of our customers. Our centerless grinding machine and resin bond CBN (Cubic Boron Nitride) centerless grinding wheels are one of our most popular products, known for their exceptional performance and reliability. We are pleased to share feedback from customers who have used our grinding wheels for various applications, particularly in grinding set screws made from a variety of challenging materials.

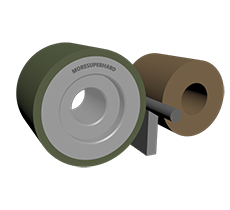

Technical Specifications of CBN Centerless Grinding Wheels

- Wheel Material: Resin bond CBN grinding wheel

- Wheel Size: 1A1 D500xH305xX10xT00mm

- Grit Size: 400#

- Workpiece: Set Screws

- Workpiece Material: Stainless steel 304, 204, 316, Monel, Inconel

- Grinding Depth: Approximately 0.010” per side

Workpiece picture of CBN Centerless Grinding Wheels

Performance and Versatility of CBN Centerless Grinding Wheels

One of the most frequently highlighted aspects of our resin bond CBN grinding wheels is their outstanding performance across a wide range of materials. Customers have successfully used these wheels to grind set screws made from stainless steel grades 304, 204, and 316, as well as more demanding materials like Monel and Inconel. The consistent feedback is that our grinding wheels maintain their sharpness and cutting efficiency, even when working with tough alloys.

Precision and Surface Finish of CBN Centerless Grinding Wheels

Customers have praised the precision of our grinding wheels, noting that they deliver consistent results with every pass. The 400# grit size provides an excellent balance between material removal rate and surface finish quality. When grinding at the specified depth of 0.010” per side, users report achieving a smooth, clean finish that meets or exceeds industry standards. This level of precision is particularly important when working with components like set screws, where dimensional accuracy is critical.

Durability and Cost-Effectiveness of CBN Centerless Grinding Wheels

Another aspect that customers appreciate is the durability of our resin bond CBN grinding wheels. The resin bond ensures that the abrasive grains are held firmly in place, leading to a longer wheel life and reduced downtime for wheel changes. This durability, combined with the wheel's ability to maintain its cutting edge, contributes to a lower overall cost of operation. Customers have noted that the long lifespan of our wheels makes them a cost-effective solution, particularly for high-volume production environments.

Compatibility and Ease of Use of CBN Centerless Grinding Wheels

Our customers have also noted the ease with which our grinding wheels can be integrated into their existing grinding setups. The standard size and configuration of the 1A1 D500xH305xX10xT00mm wheel make it compatible with a wide range of centerless grinding machines. Additionally, users have commented on the minimal setup time required to get the wheels running efficiently, allowing them to focus on production rather than adjustments.

Conclusion of Customer's Feedback

The feedback we've received from customers using our resin bond CBN centerless grinding wheels has been overwhelmingly positive. From their performance on tough materials like Monel and Inconel to their precision and durability, these wheels have proven to be a valuable asset in the production of set screws and other components. We are proud to continue providing grinding solutions that help our customers achieve their manufacturing goals with efficiency and confidence.

If you're looking for a reliable, high-performance grinding wheel for your centerless grinding operations, our resin bond CBN wheels are an excellent choice. We invite you to experience the quality and performance that our customers have come to trust.